Mastering Universal Joint Replacement: Step-by-Step Guide and Expert Tips

Table of Contents:

- Introduction

- Understanding the Universal Joint (U-Joint)

- Tools and Equipment Needed for U-Joint Removal

- Step-by-Step Guide: Removing the U-Joint

4.1 Removing the Bearing Caps

4.2 Inspecting the Trunnion

- Diagnosis: Needle Bearing Wear or Burn

- The Importance of Eye Protection

- Removing the Snap Rings from the Yoke

7.1 Removing Inside Snap Rings

7.2 Removing Outside Snap Rings

- Methods for Removing the U-Joint

8.1 Using a Press

8.2 Using a Hammer

- Cleaning the Snap Ring Grooves

- Preparing for Installation

10.1 Cleaning the U-Joint Holes

10.2 Adding Grease to the New U-Joint Cap

- Installing the New U-Joint

11.1 Inserting the Trunnion and Cap

11.2 Using a Press to Seat the Cap

- Inserting the Snap Rings

12.1 Installing Inside Snap Rings

12.2 Installing Outside Snap Rings

- Additional Tips for Installation

13.1 Avoiding Damage with a Ball Peen Hammer

13.2 Seating the Cap with a Flat-Faced Punch

- Relieving Pressure and Testing the U-Joint

- Installing the Attaching Yoke

- Lubricating the U-Joint

- Conclusion

Introduction

Powertrain Industries, the leader in driveline innovation and solutions, is here to guide you on how to remove a universal joint (U-joint) from your vehicle's driveshaft. The U-joint plays a crucial role in connecting the driveshaft to the transmission or differential, allowing for smooth power transfer. Over time, U-joints can wear out and require replacement. In this article, we will provide you with a step-by-step guide on removing a U-joint safely and correctly.

Understanding the Universal Joint (U-Joint)

Before we dive into the removal process, it's important to understand what a U-joint is and how it functions. A U-joint consists of four main components: two bearing caps, a trunnion, and needle bearings. Its purpose is to transmit rotational power while accommodating angular misalignment between two shafts. By allowing the driveshaft to flex and rotate, the U-joint ensures smooth power delivery even when the vehicle is in motion.

Tools and Equipment Needed for U-Joint Removal

To successfully remove the U-joint, you will need a few essential tools and equipment. Make sure you have the following items on hand before starting the removal process:

- Safety goggles or glasses

- Snap ring pliers

- Flathead screwdriver

- Hammer

- U-joint cradle or table vise

- Impact socket with a hole

- Press (optional)

Step-by-Step Guide: Removing the U-Joint

Now let's get into the step-by-step process of removing the U-joint from your driveshaft. Follow these instructions closely to ensure a safe and effective removal:

-

Removing the Bearing Caps

- Inspect the trunnion for wear or burn and wipe off any excess grease or dirt for a thorough examination.

- Use snap ring pliers or a flathead screwdriver to remove the snap rings from the yoke. Be cautious of the type of snap ring (inside or outside) and choose the appropriate tool for removal.

-

Inspecting the Trunnion

- Examine the condition of the trunnion to determine if it needs replacement. If there is significant wear or damage, it's time to replace the U-joint.

-

Diagnosis: Needle Bearing Wear or Burn

- Learn to identify the signs of needle bearing wear or burn on your U-joint. This understanding will help you determine if replacement is necessary.

-

The Importance of Eye Protection

- Before proceeding with the U-joint removal, prioritize your safety by wearing proper eye protection.

-

Removing the Snap Rings from the Yoke

- Depending on the type of snap ring (inside or outside), use snap ring pliers or a flathead screwdriver to remove the clips securing the U-joint to the yoke.

-

Methods for Removing the U-Joint

- Whether you choose to use a press or a hammer, we will guide you through the process of safely removing the U-joint from the driveshaft yoke.

-

Cleaning the Snap Ring Grooves

- It is crucial to clean the snap ring grooves to ensure a proper seating for the new snap rings.

-

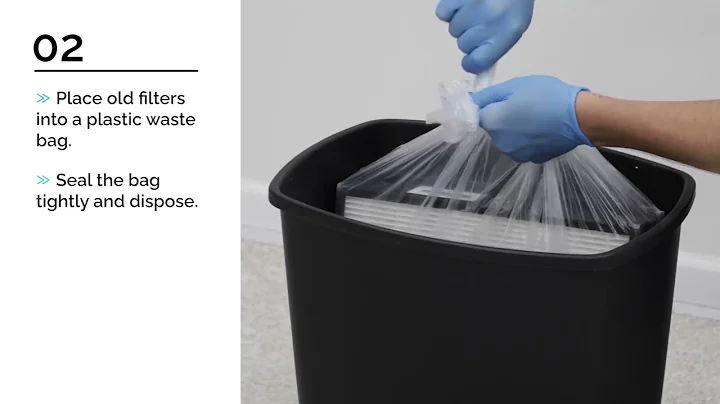

Preparing for Installation

- Before installing the new U-joint, make sure to clean the U-joint holes and add grease to the new U-joint cap for adequate lubrication.

-

Installing the New U-Joint

- Learn the correct procedure for inserting the trunnion and cap, and how to use a press to seat the cap securely.

-

Inserting the Snap Rings

- Discover the steps for properly installing the snap rings, whether they are inside or outside snap rings.

-

Additional Tips for Installation

- Avoid damaging the U-joint cap internally by using the proper hammer technique. Use a flat-faced punch to seat the cap correctly and securely.

-

Relieving Pressure and Testing the U-Joint

- Learn techniques for relieving pressure on the U-joint and ensuring smooth rotation before completing the installation process.

-

Installing the Attaching Yoke

- If you have an attaching yoke, follow the same steps for installation while being cautious of maintaining the integrity of the yoke seal surface.

-

Lubricating the U-Joint

- After the installation, ensure proper lubrication by purging grease through all four caps.

Conclusion

Congratulations! You have successfully removed and replaced the universal joint (U-joint) in your vehicle's driveshaft. By following this guide, you have gained the knowledge and skills to perform this essential maintenance task. Remember to prioritize safety by wearing eye protection and using the correct tools throughout the process. Stay tuned for more informative episodes from Powertrain Industries on driveline maintenance and solutions.

Highlights:

- Learn how to safely remove and replace the universal joint (U-joint) in your vehicle's driveshaft.

- Understand the components and function of the U-joint in the powertrain system.

- Equip yourself with the necessary tools and equipment for a successful removal.

- Follow a detailed step-by-step guide for U-joint removal with options for using a press or a hammer.

- Clean the snap ring grooves and prepare the U-joint for installation.

- Get expert tips for seating the caps properly and ensuring a secure installation.

- Maintain the integrity of attaching yokes and yoke seal surfaces during the process.

- Properly lubricate the U-joint after installation for optimal performance.

FAQ:

Q: How often do U-joints need to be replaced?

A: U-joint replacement frequency varies depending on several factors such as the vehicle's usage, maintenance, and driving conditions. However, it is generally recommended to inspect U-joints regularly and replace them if any signs of wear or damage are detected.

Q: What are the signs of a failing U-joint?

A: Some common signs of a failing U-joint include squeaking or clunking noises while driving, vibrations in the vehicle, and difficulty when maneuvering or changing gears. If you experience any of these symptoms, it is advisable to inspect and potentially replace the U-joints.

Q: Can I replace a U-joint myself, or should I consult a professional?

A: While it is possible to replace a U-joint yourself, it requires some mechanical knowledge and the right tools. If you are not confident in your abilities or lack the necessary tools, it is recommended to consult a professional mechanic for assistance.

Q: Are all U-joints the same size and shape?

A: No, U-joints come in different sizes and shapes to accommodate various driveshaft and yoke configurations. It is essential to select the correct U-joint based on your vehicle's specifications and manufacturer recommendations.

Q: Can I reuse the old snap rings when installing a new U-joint?

A: It is generally recommended to replace the old snap rings with new ones when installing a new U-joint. Fresh snap rings ensure proper functionality and secure attachment of the U-joint to the yoke.

Resources: