Revolutionary Advances in Automatic Screen Printing

Table of Contents:

- Introduction

- Efficiency and Environmental Impact of Automatic Systems

- The Role of RQ Screen Printing Press

- Lotus Machine: Automatic Screen Cleaning and Reclaiming

- Complicating Factors in Screen Printing

- Advantages of Screen Printing over Digital Printing

- Durability and Vibrancy of Screen Printing

- The Cost of Automatic Screen Printing Machines

- Considerations for Small and Large Print Shops

- Impact of Automatic Systems on Personnel and Environment

🌟 Article - Automatic Screen Printing: Efficiency, Durability, and Environmental Impact

Screen printing has long been a popular choice for many industries due to its reliability and consistent print quality. However, the preparation and cleaning of screens can be a challenging and time-consuming process. In recent years, automated systems have emerged as a solution to streamline these tasks and reduce the environmental impact of screen printing.

Efficiency and Environmental Impact of Automatic Systems

🌟 Automatic systems have revolutionized the screen printing industry by significantly improving efficiency and reducing labor-intensive processes. These systems eliminate the need for manual screen preparation and cleaning, making the production process faster and more cost-effective. With automated screen printing, companies can achieve higher output rates and meet tight deadlines with ease.

Moreover, the environmental impact of screen printing has always been a concern. Traditional methods involve the use of large amounts of chemicals and generate substantial waste, such as film and ink residue. Automatic systems address this issue by minimizing waste and optimizing resource utilization. By reducing the use of chemicals and materials, they help reduce the carbon footprint of the printing process.

The Role of RQ Screen Printing Press

🌟 The RQ screen printing press is a prominent name in the industry, known for its advanced features and capabilities. This machine offers automated screen cleaning and reclaiming, making it an essential tool for screen printing companies. By automating the cleaning process, the RQ screen printing press helps streamline production and reduce downtime.

With this automated system, screen preparation and cleaning are no longer a complicated and time-consuming task. The RQ screen printing press ensures consistent results by precisely controlling every aspect of the process. This eliminates human errors and reduces the need for manual intervention, enhancing the overall efficiency and productivity of the print shop.

Lotus Machine: Automatic Screen Cleaning and Reclaiming

🌟 The Lotus machine developed by Lotus Holland is another remarkable addition to the world of automatic screen printing. This machine specializes in screen cleaning and reclaiming, playing a crucial role in the post-press phase of screen printing. After a screen has been used, the Lotus machine efficiently removes the ink and emulsion, preparing the screen for future use.

The manually intensive job of reclaiming screens has always been a challenge for screen printers. However, with the Lotus machine, this task becomes much simpler and less time-consuming. By automating the screen cleaning and reclaiming process, companies can save valuable resources, reduce costs, and achieve higher productivity levels.

Complicating Factors in Screen Printing

🌟 Screen preparation and screen cleaning have often been cited as the most complicating factors in the screen printing process. Traditional methods involve manually coating screens with emulsion, a process prone to human errors and variations. Similarly, cleaning screens after printing requires meticulous attention to detail to ensure proper removal of ink and emulsion residue.

However, with the introduction of automatic systems, these complicating factors are significantly mitigated. Automated machines can precisely coat screens with emulsion, ensuring consistent results and reducing the risk of errors. Furthermore, the automated cleaning and reclaiming process eliminates the need for manual and time-consuming labor, enhancing efficiency and overall print quality.

Advantages of Screen Printing over Digital Printing

🌟 Screen printing offers several distinct advantages over digital printing, making it a preferred choice for many applications. Firstly, screen printing allows for a thicker layer of ink to be applied to the substrate, resulting in higher vibrancy and more accurate colors. This makes it ideal for projects that require long-lasting and durable prints, especially for outdoor use.

Additionally, screen printing provides superior color accuracy, as each color is printed individually using separate screens. This allows for better color matching and precise reproduction of intricate designs. Moreover, screen printing is highly versatile and can be used on a wide range of materials, including fabric, glass, metal, and plastic.

Durability and Vibrancy of Screen Printing

🌟 The durability and vibrancy of screen printing are unmatched by any digital printing method. The thicker layer of ink applied during the screen printing process ensures that the prints can withstand harsh environmental conditions and extended use without fading or deteriorating. This makes screen printing particularly suitable for outdoor signage, promotional materials, and apparel printing.

Furthermore, the vibrant colors achieved through screen printing add a visual appeal to products and designs. Whether it's a bold and eye-catching graphic on a t-shirt or a vivid logo on a promotional banner, screen printing guarantees high-quality and striking results. The durability and vibrancy of screen printing make it a top choice for businesses seeking long-lasting and impactful marketing materials.

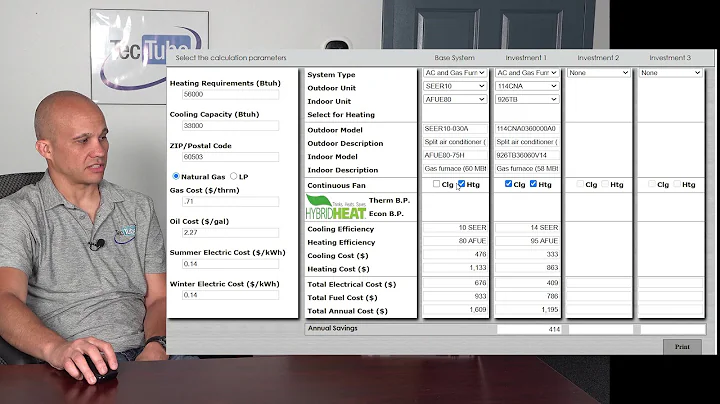

The Cost of Automatic Screen Printing Machines

🌟 Automatic screen printing machines offer efficiency and improved production rates, but they come at a cost. The price of these machines varies depending on their configuration and capabilities. Generally, the cost ranges from $50,000 to $150,000, making them a significant investment for print shops.

However, the cost of automatic screen printing machines should be evaluated in terms of the company's production volume. Smaller print shops may find it challenging to justify the investment, as the break-even point is typically around 10 screens per day. Nevertheless, as the number of screens printed increases, the ROI becomes more apparent, making the investment in automation financially viable.

Considerations for Small and Large Print Shops

🌟 While larger companies might reap the benefits of automatic screen printing more quickly, smaller print shops can also find value in adopting this technology. Automating the screen preparation and cleaning processes not only improves efficiency but also reduces the burden on personnel. The elimination of manual labor in the most challenging and time-consuming aspects of screen printing allows employees to focus on higher-value tasks, such as design and customer service.

Moreover, the environmental impact of screen printing is a growing concern for companies of all sizes. Automatic systems significantly reduce waste generation and the use of harmful chemicals, making the printing process more sustainable and eco-friendly. By investing in automation, small print shops can align themselves with environmental goals and contribute to a greener future.

Impact of Automatic Systems on Personnel and Environment

🌟 The shift towards automation in screen printing has a positive impact on both personnel and the environment. By taking over the labor-intensive and often messy tasks of screen preparation and cleaning, automatic systems improve working conditions for employees. This minimizes the exposure to chemicals and reduces the physical strain associated with screen printing.

Furthermore, the environmental benefits of automation cannot be overlooked. Traditional screen printing methods produce significant amounts of waste, including ink residue and single-use film. Automatic systems, on the other hand, optimize resource utilization, reduce waste generation, and minimize the carbon footprint of the printing process. This makes them essential tools in the quest for sustainable and eco-friendly printing practices.

Highlights:

- Automatic screen printing systems revolutionize efficiency and reduce environmental impact.

- RQ screen printing press and Lotus machine automate screen cleaning and reclaiming processes.

- Screen printing offers superior durability, vibrancy, and color accuracy compared to digital printing.

- Automatic systems streamline complicated aspects of screen printing, such as screen preparation and cleaning.

- Automating screen printing processes improves productivity and reduces labor-intensive tasks.

- Automatic systems significantly reduce waste generation and the use of harmful chemicals.

- The cost of automatic screen printing machines varies but can be financially viable for high-volume production.

- Both small and large print shops can benefit from adopting automatic screen printing technology.

- Automation improves working conditions and reduces the environmental footprint of the printing industry.

FAQ:

Q: How does automatic screen printing reduce the environmental impact?

A: Automatic systems minimize waste generation and optimize resource utilization, reducing the use of chemicals and materials in the printing process. This helps reduce the carbon footprint and make the process more sustainable.

Q: Is screen printing more durable than digital printing?

A: Yes, screen printing offers superior durability, especially for outdoor use. The thicker layer of ink results in long-lasting and fade-resistant prints that can withstand harsh environmental conditions.

Q: What is the cost range of automatic screen printing machines?

A: The cost of automatic screen printing machines typically ranges from $50,000 to $150,000, depending on their configuration and capabilities.

Q: Can small print shops benefit from automatic screen printing?

A: Yes, small print shops can also benefit from automation by improving efficiency and reducing the burden on personnel. Automating labor-intensive tasks allows employees to focus on higher-value activities.

Q: How do automatic systems impact working conditions?

A: By taking over labor-intensive tasks, automatic systems improve working conditions by reducing exposure to chemicals and physical strain associated with screen printing.

Resources: