Solving No Spark/No Fire Issue - Gravely Walk Behind Tractor

Table of Contents

- Introduction

- The Problem with the Filter

- Stiff Choke and Cable Maintenance

- Checking for Spark

- The Kill Switch Issue

- Disassembling the Magneto

- Cleaning the Points

- Conclusion

Article

Introduction

Have you ever encountered a frustrating situation where your machinery just doesn't seem to work properly? Well, I recently found myself in such a predicament when I decided to take a look at the inner workings of my equipment. What I discovered was quite alarming and required immediate attention. In this article, I will share my experience and the steps I took to resolve the issues I encountered. So, if you've ever struggled with a malfunctioning filter, a stiff choke, or a faulty spark, read on to find out how I tackled these problems.

The Problem with the Filter

First on my list of issues was a malfunctioning filter. It was clear that the filter had seen better days, with debris and even a piece of grass making themselves comfortable inside it. This was not only unsightly but also detrimental to the proper functioning of the equipment. I quickly realized that the filter needed to be replaced, as it was hindering the smooth flow of air and potentially causing damage to the machinery. I carefully removed the old filter and disposed of it, making sure to clean the surrounding area thoroughly to avoid any further complications.

Stiff Choke and Cable Maintenance

Next up was the issue with the stiff choke and the locked-up throttle cables. It appeared that both components were in dire need of some care and attention. To rectify this, I lubricated the choke to ensure smooth operation and performed maintenance on the cables to free them up. This simple task greatly improved the functionality of the equipment and created a more user-friendly experience.

Checking for Spark

With the basic maintenance tasks out of the way, I turned my attention to the crucial matter of checking for spark. Without a proper spark, the machinery would fail to start, rendering all other efforts useless. I followed the instructions in the owner's manual and verified that the throttle was in the correct position while fully choking the equipment. However, even after adding fuel and attempting to start it, there was no sign of life. This led me to dig deeper into the issue, suspecting a possible grounding problem.

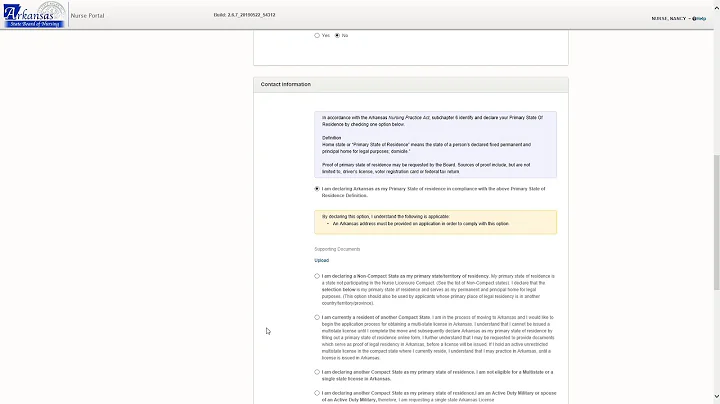

The Kill Switch Issue

Upon inspection of the Magneto, I discovered that there was a wire causing a short circuit. Thankfully, this was not a complicated problem to solve. I traced the wire to the two kill switches on the equipment, one located on the magnetic case and another on the handlebar. Using a multimeter, I determined that there was continuity between the two switches, meaning the circuit was constantly grounded, preventing the spark from occurring. To remedy this, I ran a wire, creating a separate channel to prevent grounding, and lubricated the area to loosen any obstruction that may have caused the issue.

Disassembling the Magneto

After tackling the kill switch problem, I proceeded to disassemble the Magneto to access the points, where the spark is generated. Carefully removing the screws and gasket, I was able to take a closer look. Although the points appeared dirty, they were still functional. To ensure optimal performance, I utilized some Emery cloth to clean the points thoroughly, removing any debris or corrosion that may have been hindering the spark.

Conclusion

In conclusion, troubleshooting and rectifying issues with machinery can be a daunting task. However, with the right knowledge and a systematic approach, even the most complex problems can be resolved. In my case, by addressing the filter, choke, cable, and spark issues, I was able to get my equipment back in working order. Remember, regular maintenance and careful inspection can go a long way in preventing major breakdowns and prolonging the lifespan of your machinery. Happy troubleshooting!

Highlights

- Identifying and replacing a malfunctioning filter

- Performing maintenance on the choke and throttle cables

- Troubleshooting spark issues and addressing grounding problems

- Disassembling the Magneto and cleaning the points

- Maintaining equipment for optimal functionality and prolonging its lifespan

FAQ

Q: How often should I replace the filter in my equipment?

A: It is recommended to replace the filter regularly, depending on the manufacturer's instructions or when signs of clogging or damage are evident.

Q: What can cause a stiff choke and locked-up throttle cables?

A: Stiff choke and locked-up throttle cables can be caused by lack of lubrication or the accumulation of dirt and debris. Regular maintenance and cleaning can prevent these issues.

Q: How can I check for spark in my equipment?

A: Follow the owner's manual instructions to position the throttle correctly, fully choke the equipment, and attempt to start it. If there is no spark, further investigation may be necessary.

Q: What should I do if the kill switch is causing grounding issues?

A: Inspect the kill switches for continuity and ensure they are not constantly grounding the circuit. Separate the wiring and lubricate the area to prevent any obstructions.

Q: How often should I clean the points in the Magneto?

A: Cleaning the points in the Magneto should be done regularly as part of routine maintenance. Frequency may vary depending on usage and manufacturer recommendations.