Building a Welding Trailer: Your Mobile Welding Solution

Table of Contents

- Introduction

- The Welding Trailer Project

- 2.1 Why I Decided to Build a Welding Trailer

- 2.2 Choosing the Right Welder

- 2.3 The Miller Bobcat: A Perfect Fit

- Planning the Trailer

- 3.1 Design Considerations

- 3.2 Materials and Tools

- 3.3 Building the Mainframe

- Mounting the Axle

- 4.1 Selecting the Torsion Axle

- 4.2 Welding and Bolting the Axle

- Setting Up the Work Area

- 5.1 Organizing the Welding Equipment

- 5.2 Installing a Jack and Hitch

- Welding and Assembly

- 6.1 Tacking and Welding the Frame

- 6.2 Adding Crossmembers

- 6.3 Finalizing the Bottom Side

- Flipping the Trailer

- 7.1 Preparation and Safety Measures

- 7.2 Using a Tractor to Flip the Trailer

- 7.3 Securing the Axle and Adding Tire Lugs

- Finishing Touches and Future Plans

- 8.1 Adding a Crossmember at the Back

- 8.2 Creating a Lifting Point

- 8.3 Potential Upgrades: Air Compressor and Tool Storage

- Conclusion

🛠️ Building a Welding Trailer: Turning Dreams into Reality

Are you a skilled welder looking for a more convenient and versatile way to utilize your welding equipment? Have you ever dreamt of having a mobile welding setup that you can take with you anywhere? Look no further! In this article, I will guide you through the step-by-step process of building your very own welding trailer. From choosing the right welder to designing the trailer, mounting the axle, welding and assembling the frame, and adding finishing touches, we will cover all the essentials to help you turn your dreams into reality.

1. Introduction

As a passionate welder, I have always sought ways to make my work more efficient and accessible. After talking to fellow welders and researching various options, I came to the conclusion that building a welding trailer would be the perfect solution. With a portable welding setup, I could take my equipment to any job site or even use it as a backup in case of emergencies. In this article, I will share with you my journey of building a welding trailer and the lessons I learned along the way.

2. The Welding Trailer Project

2.1 Why I Decided to Build a Welding Trailer

The decision to build a welding trailer stemmed from my desire for mobility and convenience. Having a dedicated trailer allows me to have a complete welding setup on the go. Whether I need to repair something on-site or lend a helping hand to a friend, having a portable welding station provides immense flexibility.

2.2 Choosing the Right Welder

Before diving into the construction of the trailer, it was crucial to select the appropriate welder for my needs. After careful research and consideration, I identified the Miller Bobcat as the ideal welder for this project. With its powerful Kubota diesel engine and exceptional welding capabilities, the Miller Bobcat became the heart of my welding trailer.

2.3 The Miller Bobcat: A Perfect Fit

Equipped with a high-speed diesel Kubota engine, the Miller Bobcat is the epitome of reliability and performance. Its compact size and 42 hours of usage make it an incredible find. The Miller Bobcat will serve as a solid foundation for my welding trailer, ensuring I have the necessary power to tackle any welding task.

3. Planning the Trailer

3.1 Design Considerations

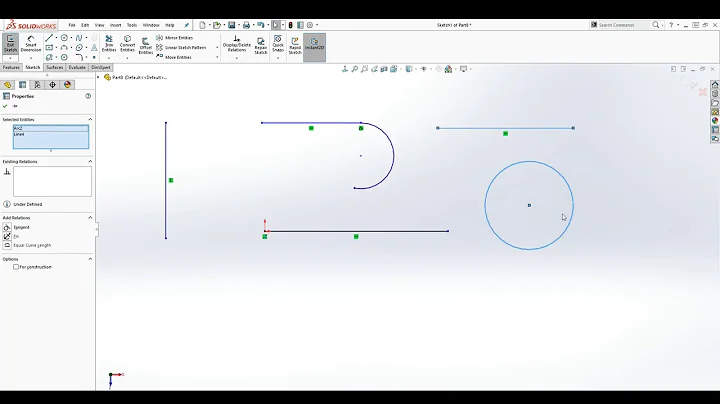

When designing the trailer, I had a clear vision in mind - versatility and practicality. I wanted the trailer to be able to accommodate not only the Miller Bobcat but also other welders, such as the 200 and 300. This meant creating a trailer with ample space and proper weight distribution. Additionally, I wanted to incorporate a mounting point for an oxygen and CO2 bottle, as well as the potential for incorporating an engine-driven air compressor.

3.2 Materials and Tools

To bring my vision to life, I gathered the necessary materials: four-inch and three-inch channel steel for the mainframe, a torsion axle salvaged from an old air compressor trailer, and a two-by-four tube for the rear crossmember. In terms of tools, I relied on my trusty welding machine, specifically the L40 220 MP model.

3.3 Building the Mainframe

To create a solid foundation for the trailer, I started by assembling the mainframe using four-inch channel steel. By welding the tongue, sides, and crossmembers together, I ensured a sturdy structure that would withstand the rigors of transportation. Proper measuring and alignment were crucial during this process to ensure a square and balanced trailer.

Stay tuned for the next part of this guide, where we will explore the process of mounting the axle and setting up the work area. Building your own welding trailer is an exciting journey, and together, we will make it a success!

Resources:

Highlights

- Building a welding trailer provides mobility and convenience for welders.

- The Miller Bobcat is an ideal welder for a welding trailer due to its power and reliability.

- Design considerations include versatility, weight distribution, and potential future upgrades.

- The mainframe of the trailer is built using four-inch channel steel for strength and durability.

- The next steps involve mounting the axle and setting up the work area.

FAQ

Q: Can the welding trailer be customized for different welders?

A: Yes, the trailer can be designed to accommodate various welders, ensuring flexibility for different welding needs.

Q: Is it possible to add an air compressor to the welding trailer?

A: Yes, by incorporating an engine-driven air compressor, the welding trailer can provide compressed air for pneumatic tools.

Q: How can I ensure proper weight distribution on the welding trailer?

A: Proper weight distribution can be achieved by considering the placement of equipment and materials, as well as using the appropriate axle and hitch.

Q: Can I use the welding trailer for other purposes besides welding?

A: Yes, the welding trailer can be used for various purposes, such as transporting equipment or serving as a general utility trailer.

Q: What safety precautions should I take when building and using a welding trailer?

A: It is essential to follow proper welding safety measures, including wearing protective gear, ensuring proper ventilation, and securing equipment during transportation.