Fixing Belt Burnouts: A Step-by-Step Guide to Servicing the Vacuum Cleaner Shaft

Table of Contents

- Introduction

- Understanding the Issue with the Shaft

- 2.1 Turning the Shaft with Your Hands

- 2.2 Rusting of the Bearings

- 2.3 Cleaning the Soot Build-up

- 2.4 Using Lubricant

- 2.5 Replacing the Shaft

- Opening the Unit

- Removing the Belt

- Removing Components

- 5.1 Removing the Side Panel

- 5.2 Removing the Coupling

- 5.3 Removing the Pump and Brush Belt

- Observing the Spray Problem

- Lifting the Shaft

- Servicing the Shaft

- 8.1 Holding and Turning the Bearings

- 8.2 Reinserting the Shaft

- Reattaching Components

- Conclusion

🔧 Understanding and Fixing Shaft Issues: A Step-by-Step Guide

Are you experiencing a problem with the shaft of your Abyssal Revolution? If you've replaced the belt, only to have it burn again, you're in the right place. In this comprehensive guide, we'll walk you through the process of addressing and resolving the shaft issue with your vacuum cleaner.

1. Introduction

Vacuum cleaners play a vital role in our everyday cleaning routines. However, they are not immune to mechanical problems. One common issue is a malfunctioning shaft, which can lead to burnt belts and decreased performance. In this article, we will guide you on how to diagnose and fix this problem step by step. Let's dive in!

2. Understanding the Issue with the Shaft

Before we jump into fixing the shaft, it's essential to understand what might be causing the problem. Here are a few factors to consider:

2.1 Turning the Shaft with Your Hands

The first step in diagnosing the issue is to check if you can manually turn the shaft with your hands. If you find it difficult or impossible to rotate, chances are the bearings are rusted. This can hinder the movement of the shaft and result in belt burnouts.

2.2 Rusting of the Bearings

Rusted bearings are a common cause of shaft issues. Over time, moisture or environmental factors can lead to rust formation, impacting the smooth rotation of the shaft. If you notice rust on the bearings, it's time to take action.

2.3 Cleaning the Soot Build-up

Apart from rust, there may be a build-up of soot on the shaft. This is a residue left behind by burnt rubber from previous belt burnouts. You can clean this off using a suitable lubricant and a cloth. Ensure you remove as much soot as possible to prevent future issues.

2.4 Using Lubricant

To address rusted bearings and improve the movement of the shaft, you can try using a spray lubricant. It's recommended to use lubricants specifically designed for these types of mechanisms. Apply the lubricant to the bearings, allowing it to penetrate and loosen any rust. This should help restore the smooth rotation of the shaft.

2.5 Replacing the Shaft

If all else fails, and the shaft does not move even after cleaning and lubrication, it may be necessary to replace it. Replacing the shaft will ensure optimal performance and prevent further belt burnouts. Consult the manufacturer's guidelines or seek professional assistance to ensure a proper replacement.

3. Opening the Unit

To access the shaft and perform necessary repairs or replacements, you'll need to open the vacuum unit. Here's how:

5. Removing Components

To gain access to the shaft, some components need to be removed. Let's go through the process step by step:

5.1 Removing the Side Panel

Start by removing the side panel of the unit. This will provide you with the initial access point to the internals.

5.2 Removing the Coupling

Next, remove the coupling located near the shaft. Ensure you handle it with care to avoid any damage.

5.3 Removing the Pump and Brush Belt

To further clear the way, detach the pump and brush belt connected to the shaft. This will allow easier manipulation of the shaft during the repair process.

6. Observing the Spray Problem

While inspecting and repairing the shaft, it's worth checking for any spray-related problems. The spray issue may be caused by a loose or ineffective belt-spray connection. Take note of any signs of wear or damage in this area.

7. Lifting the Shaft

Once you have removed the necessary components, it's time to lift the shaft out for closer examination. Follow these steps:

7.1 Noting the Position

Before removing the shaft, take note of its position. It forms a U-shape when properly installed. This will ensure you can place it correctly during reassembly.

8. Servicing the Shaft

Now comes the crucial part: servicing the shaft. Pay close attention to these steps:

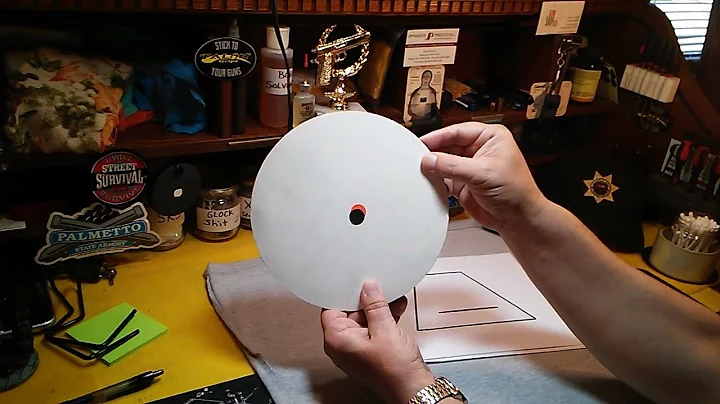

8.1 Holding and Turning the Bearings

Hold the bearings firmly and try turning the shaft manually. If you encounter resistance or the shaft doesn't rotate smoothly, it's an indication that further action is required. Properly functioning bearings should allow smooth and effortless rotation.

8.2 Reinserting the Shaft

If the shaft needs to be replaced, carefully insert the new one into the same position as the original. Ensure it matches the U-shape and aligns with the surrounding components.

9. Reattaching Components

Once the shaft has been serviced or replaced, it's time to reattach the components you removed earlier. Follow the reverse order of removal to ensure everything is properly secured.

10. Conclusion

Congratulations! You have successfully addressed the shaft issue with your vacuum cleaner. By following this step-by-step guide, you have learned how to diagnose, service, and replace the shaft when necessary. Remember, regular maintenance and timely repairs are crucial for keeping your vacuum cleaner in top shape.

🔧 Pros:

- Easy to follow steps

- Allows for DIY troubleshooting and repairs

- Prevents further belt burnouts

- Improves the performance of the vacuum cleaner

🔧 Cons:

- Requires some level of technical knowledge

- May need specialized tools for certain tasks

- Replacement of shaft might be necessary in some cases

Highlights:

- Identify the issue with the shaft of your vacuum cleaner

- Understand the common causes, such as rusted bearings

- Clean the soot build-up and use lubricant for smoother rotation

- Replace the shaft if necessary

- Open the unit and remove components for access

- Pay attention to any spray-related problems

- Lift and service the shaft, checking the bearings

- Reattach the components in the correct order

- Regular maintenance is crucial for optimal vacuum cleaner performance

FAQs

Q: How do I know if my vacuum cleaner shaft is the problem?

A: If you've replaced the belt and it continues to burn, or if you can't manually turn the shaft, it's likely the shaft is the culprit.

Q: Can I use any lubricant for the shaft?

A: It's best to use lubricants specifically designed for mechanical components. Avoid using WD-40 and opt for lubricants available at auto stores.

Q: Do I need special tools to perform these repairs?

A: While some tasks may require specific tools, basic household tools like a screwdriver should suffice for most tasks.